How To Install Chimney Range Hood

Earlier Installation: Inspecting Your Vent Hood

Earlier showtime your installation, there are a few things to keep in mind. Once y'all receive the hood, inside 24-36 hours, be sure to take the hood out of the box to inspect it for whatever damage. Make sure y'all have all the parts also and that these parts are in expert status. Most chiefly, plug your range hood in and ensure that information technology works properly. The last thing you lot want is to waste time installing a faulty range hood.

For Correct Venting – Dos and Don'ts

Dos

- Allow 28-36″ betwixt the top of the cooking surface and the bottom of the hood.

- Permit 36-42" for venting over a BBQ grill.

- The all-time option is to vent vertically through the roof if possible. Vent through a side wall if you cannot vent directly above your hood.

- Apply galvanized steel or metal HVAC ducting only.

- For all-time functioning, use as few elbows as possible with no more than than three ninety° elbows. Include at least 18″ straight from the transition piece earlier using an elbow in the duct and make sure there is at least 24″ of straight vent betwixt any other elbows.

- Use HVAC record to seal all joints in the vent system.

- Use caulking to seal exterior openings around the cap.

- Ever go on the duct clean to ensure proper airflow.

Don'ts

- Terminate the vent arrangement into an attic or another enclosed area.

- Mount the range hood exterior of the 28″-36″ height above the cooking surface. Hoods mounted besides low may be susceptible to heat or fire damage. Hoods mounted too loftier will perform poorly and go inefficient.

- Use 4″ (10.two cm) laundry-type wall caps.

- Employ plastic venting or plastic ducting.

- Install a range hood lower than 36″ over a BBQ.

- Use more 35' of ductwork.

- Reduce the diameter of your ductwork from the hood outlet size.

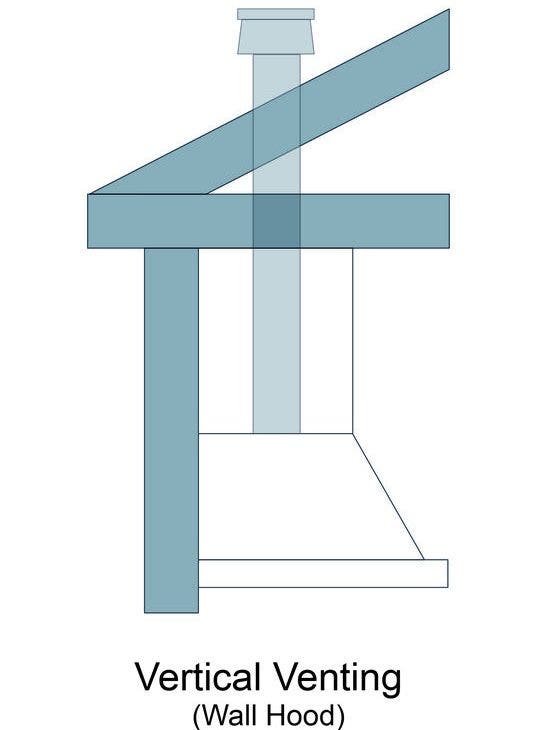

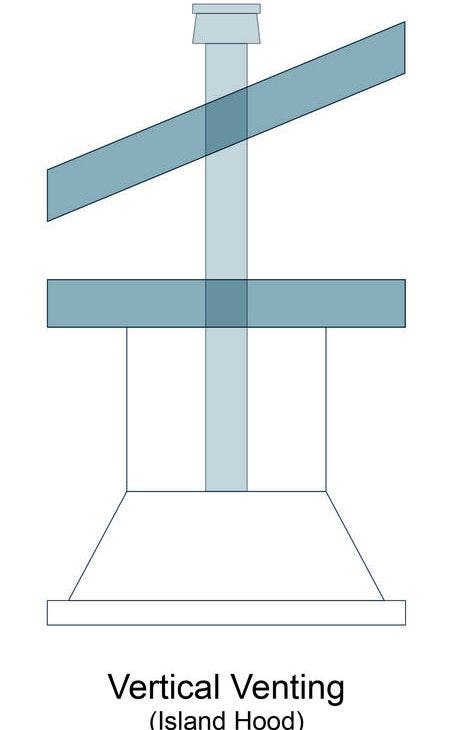

Vertical Roof Venting

Vertical roof venting is the virtually efficient way to vent and the preferred venting option for all wall mounted or island hoods. A roof cap is needed to protect the ducting from the exterior. Seal the roof cap with caulking.

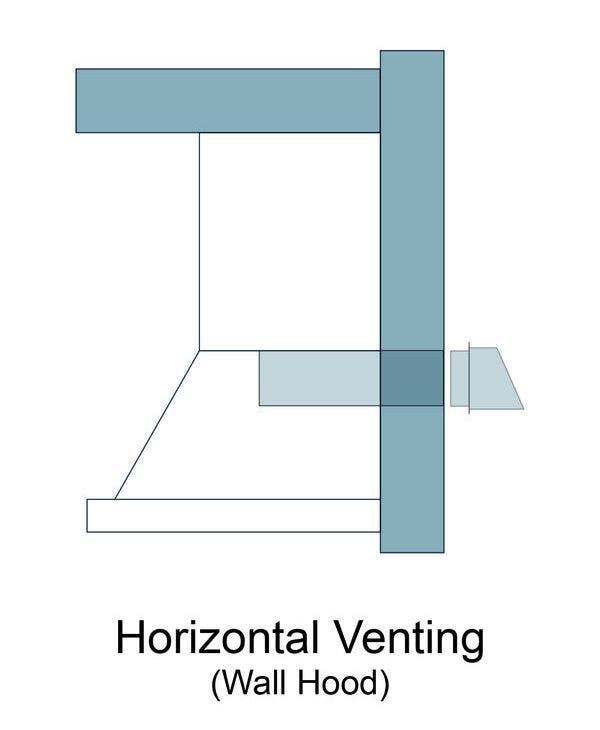

Horizontal Wall Venting

Option 1

This is an culling option to vertical venting. Ducting goes horizontally from the range hood through the house'southward side wall. Depending on the model of hood, venting can go straight through an exterior wall from the dorsum of the hood if the hood has an option to rotate the blower panel (Option 1). This choice is only bachelor on specific models.

Option 2

The 2nd option is to vent from the top of the blowers and elbow through the wall (Option ii). For correct venting, please allow at least eighteen″ of straight vertical travel from the tiptop of the transition slice before attaching the elbow. A side wall cap is needed to protect the ducting from the exterior. Seal the side wall cap with caulking.

Additional Options

- These are culling options to vertical venting. Ducting goes through the kitchen ceiling from the elevation of the hood then through a nearby exterior wall.

- For wall hoods, it is recommended to vent out of the wall that the hood is mounted on to use the least amount of ductwork. For island hoods the nearest exterior wall in whatever direction is recommended for venting.

- A side wall cap is needed to protect the ducting from the exterior. Seal the side wall cap with caulking.

Wall Hood Installation

What You Will Need

- Power Drill

- Screwdrivers

- Drill Bits

- Record Measure

- Masking Tape

- Pencil/Marker

- Metal or Aluminum HVAC

- Tape

- Level

- Wall Anchors*

- Scissors/Box Cutter

NOTE: The range hood needs to be installed to secure studs or supports. Wall anchors can be used for additional support and will vary depending on the wall material and the weight of the range hood existence installed.

Audit Range Hood

Cheque the contents of your box. They should include, depending on the specific model of your hood:

- Range Hood Wall or Ceiling Mounting Bracket Hardware

- Chimney

- Support Brackets

- Transition Duct

As you inspect your hood:

- Plug in and test controls, lights, and fan.

- Inspect for whatsoever damage caused during shipping.

- Report any damage to Proline Customer Service within fourteen days of receipt of hood by calling 877.901.5530 or emailing support@prolinerangehoods.com.

Notation: Do non install if the hood is damaged or you are unsatisfied with it.

Fix Ductwork

Plan where your ductwork volition exist located. Install the proper sized ductwork and exterior roof or wall cap, depending on where you lot volition be venting your hood to the outside. The ductwork should already be punched through the ceiling (or wall if the ceiling is not an option) and ready to hook upwardly to the range hood before outset installation. Run into venting requirements above.

Wall Hood Installation – Measurements

Earlier beginning your installation, describe these markings on the installation surface area wall:

- The center line of installation area.

- The location of wall studs nearest to the center line. (I on each side)

- A horizontally level line 28-36″ above the cooktop surface. This is where the bottom of your range hood will exist.

Step 1 – Detect location for mounting the range hood

- Trace the outline of your hood on a panel of its cardboard box.

- Find the mounting holes and center bespeak of the hood (directly between the mounting holes) and mark them on the paper-thin console.

- Advisedly cut out the paper-thin outline.

- Tape the cardboard cutout panel to the wall lining information technology up with the horizontal line (bottom of hood location) and matching the center signal with the centerline of the installation area.

- Poke holes through the mounting points on the cardboard marking the locations on the wall and remove the cardboard.

- If using wall anchors, pre-drill the mounting holes where your marks are with the correct size bit and insert the wall anchors.

- Notation: The range hood needs to be installed in secure studs or supports. Wall anchors can be used for additional support and will vary depending on the wall material and the weight of the range hood beingness installed

- Screw in mounting screws to the marked studs and or wall anchors, leaving roughly a i/iv″ gap. This gap will be used to hang the hood in Footstep iii.

Step ii – Install Ceiling Chimney Bracket

- Place the chimney bracket against the ceiling, matching the middle point of the subclass with the centerline of the installation area.

- Marking the locations of the bracket holes on the wall and drill the holes where the locations are marked.

- Insert wall anchors in the drilled holes and spiral the bracket into identify. The chimney volition mount to the subclass.

Pace 3 – Hang Range Hood

- Hang the hood on the mounting screws in place from Step 1. Tighten the mounting screws to secure the hood. The bottom of the hood should lucifer up with the horizontal line marked on the wall.

- Drill holes in the dorsum of the hood lining upwards with the wall studs that have been previously marked.

- Secure the hood to the wall studs using the screws included in the hardware pocketbook.

- Attach the previously installed ductwork to the hood's blowers, taping information technology in identify using duct tape or HVAC tape.

- Power the hood by connecting the three pronged plug to a nearby electrical outlet or past hardwiring the hood to a power source.

- NOTE: Always consult an electrician earlier directly wiring a hood to a ability source.

Footstep 4 – Install Chimney

Annotation: Not all styles of wall mount range hoods have chimneys. Under cabinet and insert styles are typically without a chimney. Chimneys normally come in two equal-sized telescoping pieces unless they are custom cut.

- Identify the two pieces of chimney on top of the range hood, making certain the vent in the upper section is towards the top and the upper section slides within the lower department in a telescoping manner.

- Attach the top section of the chimney to the mounting bracket, allowing the bottom section of the chimney to rest deeply on the top of the hood.

- Spiral the base of the chimney to the summit of the hood (if there are mounting holes bachelor).

Island Range Hood Installation

What You lot Will Need

- Power Drill

- Screwdrivers

- Drill Bits

- Record Measure out

- Masking Tape

- Pencil/Marker

- Metal or Aluminum HVAC Record

- Plumb Bob/Laser Level

- Scissors/Box Cutter

- 2x4s or Appropriate Framing Material*

NOTE: *2x4s and other additional framing material may be required if you are installing actress supports or if the ceiling joists are not close to the range hood.

Within 14 days of receiving your hood, audit it fully and test that it is working properly. Later on xiv days, you will not be able to render your hood.

Inspect Range Hood

Cheque the contents of your box. They should include:

- Range Hood

- Ceiling Mounting Bracket

- Hardware Bag

- Chimney Support Brackets

- Transition Duct (applies to specific models)

Earlier installation:

- Plug in and test controls, lights, and fan.

- Inspect for whatsoever damage caused during shipping.

- Report any damage to Proline Customer Service within 14 days of receipt of hood past calling 877.901.5530 or emailing support@prolinerangehoods.com.

Notation: Practise not install if the hood is damaged or y'all are unsatisfied with it.

Prepare Ductwork

Plan where your ductwork volition be located. Install the proper sized ductwork and exterior roof cap, depending on where yous will exist venting your hood to the outside. Ductwork should be ready to hook upwardly to the range hood before beginning installation. Run across venting requirements above. *Measurements

Get-go draw these markings on the installation area ceiling:

- Center foursquare of installation area

- Location of ceiling joists nearest to the installation area. (One on each side)

Pace 1 – Finish Mark Ceiling

- Find the joists in your ceiling.

- Find and mark the center point directly above your cooktop using a plumb bob or light amplification by stimulated emission of radiation level to line them upwards accurately.

- Place the ceiling subclass on the ceiling around the center point. (Make certain it is square with your cooktop.) Ensure that the subclass intersects the joists in your ceiling. If it doesn't, you must frame supports for securing the ceiling bracket. For best results, consult a building professional.

- Trace the outline of the ceiling bracket onto the ceiling.

- Trace a circumvolve where the ducting will go.

- Mark the four corners where you will drill the holes.

Step 2 – Install Ceiling Subclass

- Drill holes into iv ceiling marks from Step ane. These holes should hit ceiling joists or the added framing.

- Cutting out a pigsty in the ceiling where the ducting will go and finish preparing the ductwork.

- Identify chimney bracket against ceiling and screw securely into place.

- Drop the ducting and electrical work through the ceiling.

Step iii – Install Support Brackets

- Place brackets vertically inside the four corners of the ceiling bracket.

- Extend the brackets to the appropriate length. (The bottom of the hood should exist 28"-36" in a higher place the cooktop).

- Screw all support brackets to the ceiling mounting bracket securing them tight.

Step iv – Install Chimney

- Slide inner chimney sleeve over support brackets, roofing the ceiling bracket.

- Spiral into identify at the pinnacle of ceiling bracket.

- Slide outer chimney sleeve over inner chimney sleeve.

- Adjust until the bottom chimney sleeve is a few inches to a higher place the bottom of the support brackets.

- You may desire to use masking tape to help hold the chimney in identify while yous proceed to Step 5.

Step 5 – Attach Hood

- If your hood comes with a transition ducting piece, secure information technology to the base of your hood before mounting.

- Place the base of the hood directly under the chimney.

- Screw hood to the support brackets on all four corners.

- Feed electrical and ducting work through chimney. • Power your hood by hardwiring your hood to a power source or by plugging information technology in to a nearby electric outlet if in that location happens to be 1 available.

Annotation: E'er consult an electrician earlier straight wiring a hood to a ability source.

- Slide outer chimney sleeve down into place, meeting the summit of the hood.

This concludes the installation of an island hood. If you accept any questions about the installation process please call Proline Customer Service at 877.901.5530 or visit prolinerangehoods.com.

Under Cabinet Hood Installation

What You Volition Need

- Power Drill

- Screwdrivers

- Drill $.25

- Record Measure out

- Masking Tape

- Pencil/Marker

- Metal or Aluminum HVAC Tape

- Level

- Wall Anchors*

- Scissors/Box Cutter

Notation: *The range hood needs to exist installed to secure studs or supports. Wall anchors can be used for additional support and will vary depending on the wall textile and the weight of the range hood being installed.

Inspect Range Hood

Bank check the contents of your box. They should include:

- Range Hood

- Wall Mounting Bracket

- Hardware Bag

- Transition Duct (applies to specific models)

Before Installing Your Hood

- Plug in and examination controls, lights, and fan.

- Inspect for any damage caused during shipping.

- Report any damage to Proline Customer Service within fourteen days of receipt of hood past calling 877.901.5530 or emailing support@prolinerangehoods.com.

NOTE: Do not install if the hood is damaged or you are unsatisfied with it.

Prepare Ductwork

Programme where your ductwork will be located. Install the proper sized ductwork and exterior roof or wall cap, depending on where you will be venting your hood to the exterior. The ductwork should already be punched through the ceiling and above cabinet, or back wall and ready to claw up to the range hood before beginning installation. See the venting requirements above.

Measurements

Start draw these markings on the installation area wall:

- Center line of installation area

- Location of wall studs nearest to the center line (ane on each side)

Step 1 – Observe Location for Mounting the Range Hood

- Trace the outline of your hood on a panel of its cardboard box.

- Observe the mounting holes and center point of the hood (directly between the mounting holes) and mark them on the paper-thin panel.

- Advisedly cut out the cardboard outline.

- Tape the cardboard cutout panel to the wall leaving a small-scale gap (roughly 1/8″) beneath the bottom of the cabinet. Lucifer the eye point with the centerline of the installation area.

- Poke holes through the mounting points on the cardboard marking the locations on the wall and remove the cardboard.

- Pre-drill the mounting holes where your marks are with the correct size drill bit.

- Spiral in mounting screws, leaving roughly a ane/iv" gap. This gap will be used to hang the hood in Step 3.

Pace 2 – Hang & Secure the Range Hood on Mounting Plate

- Advisedly hang the hood on the mounting screws in place from Step 1. Tighten the mounting screws to secure the hood. The bottom of the hood should friction match upwardly with the horizontal line marked on the wall.

- Using the knockouts in the top of the hood, screw the elevation of the hood in to the bottom of the cabinet in a higher place.

- Drill holes in the back of the hood lining upwardly with the wall studs that have been previously marked, iIf the knockouts in the back of the hood do not match up.

NOTE: Use an appropriate drill bit for the mounting screws included in the hardware purse.

- Secure the hood to the wall studs using the screws included in the hardware bag. Additionally, you lot may use the knockouts in the dorsum of the hood to add more screws.

- Adhere the previously installed ductwork to the hood's blowers, taping it in identify using aluminum or HVAC tape.

- Ability the hood by connecting the 3 pronged plug to a nearby electrical outlet or past hardwiring the hood to a power source.

Notation: Ever consult an electrician before direct wiring a hood to a power source.

This concludes the installation of an under cabinet hood. If you have any questions about the installation procedure please call Proline Client Service at 877.901.5530 or visit prolinerangehoods.com.

Recirculating Air Kit Preparation

What You Will Need

- Ability Drill

- Woods Screws

- Tape Mensurate

- 6-eight Cocky-Borer Metallic Screws

- Double Sided Cream Tape

- Pencil

Inspect Recirculating Kit

- Cheque the contents of your box. They should include:

- Recirculating Kit

- Charcoal Filter (pre-installed)

- Inspect for whatsoever damage caused during shipping.

- Report any damage to Proline Customer Service inside 14 days of receipt of hood past calling 877.901.5530 or emailing support@prolinerangehoods.com.

Notation: Do non install if the recirculating kit is damaged or you are unsatisfied with it.

Nether Cabinet Installation

Recirculating kits can merely be installed over under cabinet hoods. Read the steps beneath to acquire how to install your recirculating kit.

- Mount the recirculating kit (A) in its desired location to the bottom of your cabinet, using forest screws or other appropriate hardware.

- Fasten the top of your hood (B) to the bottom of the recirculating kit (A) by using vi-8 evenly spaced self-tapping screws (C).

- Join the meridian console of the hood to the bottom flange of the recirculating kit by drilling and placing these screws from the underside of the hood.

- Optional: Apply strips of self-stick, double sided foam tape (D) around the bottom perimeter of the recirculating kit before joining with screws to provide more than adhesion, minimize rattling, and dampen noise.

- Finish installation past mounting the hood and recirculating kit, through the back of the hood, to the desired location on the wall. Follow the detailed directions in the previous section, Under Cabinet Hood Installation pg 20.

This concludes the installation of an inline blower. If you have any questions about the installation process please call Proline Customer Service at 877.901.5530 or take a look at our instructional videos for more information.

Inline Blower Installation

What Yous Will Demand

- Power Drill

- Screwdriver

- Drill Bits

- 2 Woods Screws or Lag Bolts*

- 2 Duct Transition Pieces**

- 12 Self Tapping Metal Screws

- Aluminum HVAC Tape 2x4s or Appropriate Framing Fabric***

*Utilise 1/4" Diameter Lag Bolts or #xiv Wood Screws to fix the blower mount bracket to the wall. Length will vary depending on fabric yous are fastening to.

**Duct transitions may exist required to step down the intake and frazzle openings of the blower to match the size of ducting y'all are using. Transition pieces tin be purchased at whatever HVAC or home improvement store.

***2x4s and other additional framing textile may exist required if installing actress supports.

Audit Range Hood

Check the contents of your box. They should include:

- Inline Blower

- Mounting Bracket

- Hardware Bag

Before Installing Your Hood

- Plug in and test controls, lights, and fan.

- Inspect for any damage caused during shipping.

- Report whatsoever harm to Proline Customer Service within xiv days of receipt of hood by calling 877.901.5530 or emailing back up@prolinerangehoods.com.

Annotation: Do not install if the hood is damaged or you are unsatisfied with information technology.

Discover Blower Mounting Location

Discover an area forth the desired path of your duct work where you have enough room to mount the inline blower and is sturdy enough to support the weight of your blower. This should be either a solid wall, a stud, office of your home's structure, or a framed area within your attic that is structurally sound plenty to mountain the blower to. Both points on the mounting bracket should exist mounted to a stud,

Prepare Ductwork

After finding your inline blower'southward mounting location, program where your duct work path will run. This includes where it volition leave your range hood, run through the inline blower, and exit your home. Install the proper sized duct piece of work along your planned road and the exterior roof or wall cap, depending on where yous volition be venting your hood to the outside. Duct work should already be run through the ceiling or dorsum wall behind your range hood and ready to hook upward to the range hood and inline blower earlier beginning installation on them. See venting requirements above.

Step 1 – Insert Mounting Screws to the Wall

- After finding a location where yous are going to mount your inline blower, find the specific location where your inline blower mounting bracket will get. Retrieve, the mounting bracket needs to be mounted to solid studs or rafters in the framing of your dwelling or attic.

- Trace the location of the big circle in the two channels of the apartment side of the mounting bracket on the wall. This is where the subclass will be mounted to the screws. See illustration for Step one (locations marked in red.)

- Using the appropriate drill bit for the hardware yous are using, pre-drill and insert the screws in your marked locations. Go out the screw head a one/4" out from the wall for at present. This gap will exist used to hang the blower and bracket while mounting them to the wall in Step 3.

Footstep 2 – Attach the Mounting Bracket to the Blower

Line up the two holes on the blower to the two curved channels on the mounting bracket that are facing away from the wall. Orient the blower and then that the longer tapered side is facing up and toward the management that the air will be forced. See Analogy for Step 2.

Fasten the blower to the mounting bracket using the machine screws provided with the blower.

Step three – Mount the Blower and Bracket to the Wall

- In one case the mounting subclass is securely fastened to the blower, hang the blower by its bracket on the screws that accept been installed in the mounting location from Step 1. See Analogy for Footstep 3 (Blower omitted for clarity.)

- Slide the blower and bracket on its channel to the left and finish fastening the two screws to securely fix the blower to its installation location.

Pace 4 – Attach Ductwork to the Blower

After installing the blower to the bracket, it is now time to install the previously installed ductwork to the blower. This may require transition pieces (B) if your inline blower (A) does not friction match the bore size of ducting (C) you lot are using. See diagrams for Step four.

If your duct work set up does not require transition pieces proceed to the next bullet point. Place the transition pieces (B) on both ends of the blower (A). Using your drill, screw three cocky-borer screws, spaced evenly around the circumference of the transitions, through the transitions into the blower. Generously wrap the seams of the connections with Aluminum HVAC tape to seal any airflow that may escape.

Place the duct work (C) on both ends of the blower (A), or pre-transitioned blower. Using your drill, spiral three self-tapping screws, spaced evenly around the circumference of the ducting, through the ducting and in to the blower or transition pieces. Generously wrap the seams of the connections with aluminum HVAC record to seal whatsoever airflow that may escape.

Step five – Run Ability to the Blower

- In one case the blower is installed, the final step is connecting the inline blower to your range hood and getting ability to them both.

- This process will depend on where you lot live and what your dwelling house's electrical code entails. Always consult a professional person electrician before powering your inline blower and range hood.

- The inline blower comes with a 110v plug which should be plugged into the corresponding outlet in the dorsum of your range hood. Run the cord down the outside of your ductwork and to the back of your range hood to be plugged in.

This concludes the installation of an inline blower. If y'all have whatever questions about the installation process please call Proline Customer Service at 877.901.5530 or take a wait at our instructional videos for more information..

ProV Installation

Option one – Local Blower Installation

- Mount the local blower and blower plate to the inside peak of your hood using the hardware provided. (If the blower is not previously installed.)

- Connect the ductwork using the supplied transition and damper with the hardware provided.

- Plug the local blower power cord into the plug-in located on the back of the control plate inside the hood.

- Using the previous sections in this guide, complete the installation of your Pro-V for your wall or island hood.

Option 2 – Inline Blower Installation

- Refer to the previous section on page 23, Inline Blower Installation, to consummate the installation of your Inline blower.

- Plug the Inline blower into the plug-in located on the back of the command plate inside the hood.

- Using the previous sections in this guide, complete the installation of the PRO-Five for your wall or island hood.

Option 3 – External Blower Installation

- Install your external or rooftop blower according to the manufacturer'south specifications.

- Connect the ductwork from the External Blower to the Pro-V hood.

- Using the previous sections in this guide, complete the installation of the PRO-Five for your wall or island hood.

Care and Cleaning

Alert

- Never put your hand into the area housing the fan while the fan is operating.

- Turn off power to the hood before cleaning.

- Make sure your cooktop and hood are absurd before cleaning.

- Completely dry the filter(s) immediately after cleaning.

California Proposition 65 Warning

THIS Production Tin EXPOSE YOU TO CHEMICALS INCLUDING CHROMIUM (HEXAVALENT COMPOUNDS), WHICH ARE KNOWN TO THE State OF CALIFORNIA TO CAUSE CANCER AND Nascency DEFECTS OR OTHER REPRODUCTIVE Impairment. FOR More than Data GO TO www.P65Warnings.ca.gov .

Cleaning Exterior Surfaces – Dos and Don'ts

Dos

- Regular care volition help preserve the appearance of your range hood.

- Always wipe stainless steel surfaces with the grain to avoid scratches.

- Clean periodically with hot soapy water and clean cotton wool cloth.

- For heavier soil, use a liquid degreaser such as 409™ or Fantastic™ and an acetone solution.

- If the hood has h2o or dirt spots, use a stainless steel cleaner on the surface. Promptly and gently remove cleaner with a soft towel or wipe.

- After cleaning, you may use non-abrasive stainless steel shine (such equally 3m™ or ZEP™) to buff out stainless luster. Always scrub lightly and with a clean cotton fiber cloth.

Don'ts

- Utilise corrosive or abrasive detergent (eg, Comet Power Scrub™ or EZOff™ oven cleaner).

- Use steel wool or scouring pads, which will scratch and damage the stainless steel surface.

- Leak cleaning solution onto or into the command console.

- Allow deposits to accumulate or remain on the hood.

- Permit salt solutions, disinfectants, bleaches, or cleaning compounds to remain in contact with the stainless steel for extended periods.

Cleaning the Filter

All Proline hoods come up with either an aluminum mesh or stainless steel baffle filter. Both types of filters are dishwasher safe for easy cleaning. If handwashing your filter, follow the instructions in the "Cleaning Exterior Surfaces" section above.

Troubleshooting

Nothing Works

- Plow on power at the circuit breaker console or fuse box. Check for a tripped breaker or a blown fuse.

- Make sure the hood primary power switch is on.

- Check the hood'due south wiring.

- Ensure that zilch is unplugged.

Lights Non Turning On

- See "Nothing Works" section.

- Swap out lights to determine if bulbs are lacking.

Range Hood Vibrates When Blower is On

- Make certain the range hood has been secured properly to the wall.

- Ensure that the blower is turned on.

Blower Organization Seems Weak

- Increase the fan speed, ensure that it is at a high plenty setting.

- Make sure the ducting is sized correctly. A range hood will not part efficiently with insufficient duct size (i.e., a nine" duct over an 8" hole)

- Check to see if the duct is clogged or if the damper unit (half-circular flapper) is installed incorrectly. A tight mesh on a side wall cap unit might besides cause restriction to the airflow.

Air Not Venting Out Properly

- Make sure there is at least 28" (71 cm) between the stove acme and the bottom of the hood.

- Reduce the number of elbows and length of ductwork. Check to ensure all joints are properly connected, sealed, and taped.

- Make certain power is on high speed for heavy cooking.

- Ensure that the air damper is not stuck in the ductwork.

- Check if the roof cap has air coming out of the meridian.

Warranty

Three Year Warranty

Parts – Three Years

For iii years from the date of original purchase, we will replace any parts or components that failed due to manufacturing defects.

Who is Covered

Only the original purchaser for residential products purchased in the continental United States (express warranty in Canada, Hawaii, and Alaska).

What Isn't Covered

- Consumable parts such every bit calorie-free bulbs and filters (stainless, aluminum, or charcoal).

- Damage due to natural wear, improper mounting, improper maintenance, or employ of abrasive cleaning products.

- Chips, dents, or cracks due to abuse, misuse, or improper installation.

- Damage acquired by accident, fire, floods, or natural disaster.

Returns and Exchanges

Upon Receipt of Hood

- Inspect your hood for any harm in aircraft.

- Plug in and test controls (lights, fan).

- Please report any harm to Proline Customer Service within xiv days of receipt of the blower past calling 877.901.5530.

NOTE: Exercise not install if the hood is damaged or you are unsatisfied with it.

Returns

Damaged Returns

- You must report harm directly to Proline within 14 days to receive a full refund.

- Send a photo or video showing the damage via email. We need this earlier nosotros can corroborate your impairment claim.

- Once your claim is approved, we will adjust for a damage pickup.

- A new replacement hood will be sent to you after the damaged hood has been picked up and is returning to us in transit.

NOTE: Costless returned shipping but applies in the 48 contiguous Usa. Hawaii, Alaska, and Canada must pay regular shipping rates.

Undamaged Returns

Contact Proline Client Support within 30 days with your intent and reason for refund

You volition pay a 20% factory restocking fee. You will be responsible for all return shipping costs. We can help arrange for a pickup if requested.

Exchanges

- You must request an exchange direct to Proline within 14 days.

- Notify united states of america of your reason for the substitution. Provide a photo if your hood is damaged.

- We will assist arrange for the render shipping of your hood.

- One time nosotros receive your original hood, we will transport the replacement hood.

Note: We volition only let i undamaged exchange per purchase. Your replacement hood must be of equal or lesser value. If the value of your replacement hood is higher, you lot will be responsible for paying the difference in price.

Return Claims Not Accustomed If…

- Hood has been installed.

- Hood has been custom cutting or otherwise contradistinct.

- Damage is reported after 14 days.

- Original packaging or parts are missing.

Final Tips For Proper Vent Hood Installation

- Ask someone to assist you with heavy lifting when placing the range hood.

- Step back and inspect your vent hood installation job. Cheque to make sure that your vent hood is functioning correctly and that information technology is placed centered and directly.

- Become back to the exterior and check for any exposed ductwork. Make certain to use a vertical cover to place over any ductwork that is not covered.

- If y'all have unique venting requirements, make certain to ask a professional for advice earlier mounting your range hood.

Nosotros hope this information helped you better sympathize how to install a vent hood. At Proline Range Hoods, we make our range hoods and vent hoods piece of cake to install at whatever step of the procedure. We also accept many videos on how to install range hoods on our website. Also, don't forget to take a moving-picture show of your range hood and send information technology to back up@prolinerangehoods.com for a run a risk to be featured on our web log and social media channels!

Source: https://www.prolinerangehoods.com/blog/how-to-install-a-vent-hood/

Posted by: oursedweess.blogspot.com

0 Response to "How To Install Chimney Range Hood"

Post a Comment